Say in the coming weeks of your ideation you spoke to people, validated your idea and say you also found some people who are genuinely interested in your product. Your product is most definitely a value addition in their lives and they are ready to pay for it as well.

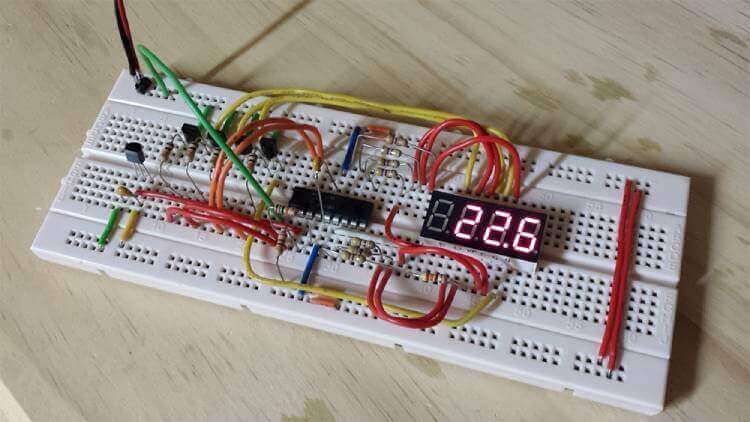

But the bigger question is what are you trying to sell? You can definitely sell an idea but if you want to build more trust then you need to show something working! This something working is called the Proof of Concept (POC).

The understanding behind creating a POC is very simple:

- The most important thing here is that you are able to validate your idea. What you have gone and sold to people and they have put their trust in you, you want to make sure you can deliver.

- Secondly, you can sell someone an idea and make the other person believe what you are saying is actually possible but getting something tangible to show and demonstrate is comparatively difficult. So creating a POC makes something tangible for you to show-and-tell.

- At the POC stage you can decide a preliminary feature set of your product. What is feasible to be added at the POC stage and what you want to keep on your product road-map are some of the things that become clear at the POC stage.

Over and above all the three points mentioned here one point needs special attention. You will be able to understand your manufacturing costs to a considerable extent. Based on the costs you will also be able to validate if the market still exists for your product. If your manufacturing costs are higher than what your target audience is ready to pay for you need to take a closer look at your product. Depending on how far off you are from the estimated cost there are several ways to go on from there but some of them are listed below:

- Re-think the features you are looking to add and see how cost can change based on that removing/modifying features.

- Re-think your target audience and try to pivot your product to a different market where people can afford your product.

- Think about how the economies of scale will work for you. What I mean is can you build a larger quantity and hence bring your costs down. The thumb rule is for every 10x the manufacturing qty you come down by 5-10% but this number goes down as the qty increases.

All the above steps that were mentioned basically point you to your Minimum Viable product (MVP). Once your MVP is decided you are ready to scale to the next level.

In conclusion, creating a POC is a great exercise. Use that exercise to your advantage and don’t treat it as a formality. Your MVP and your road-map can really make or mar your product/company’s future

This is the third article of a series of articles that we are publishing. If you have just logged in please refer to the previous article here.

About Ambimat Electronics:

With design experience of close to 4 decades of excellence, world-class talent, and innovative breakthroughs, Ambimat Electronics is a single-stop solution enabler to Leading PSUs, private sector companies, and start-ups to deliver design capabilities and develop manufacturing capabilities in various industries and markets. AmbiIoT design services have helped develop Smartwatches, Smart homes, Medicals, Robotics, Retail, Pubs and brewery, Security.

Ambimat Electronics has come a long way to become one of India’s leading IoT(Internet of things) product designers and manufacturers today. We present below some of our solutions that can be implemented and parameterized according to specific business needs. AmbiPay, AmbiPower, AmbiCon, AmbiSecure, AmbiSense, AmbiAutomation.

To know more about us or what Ambimat does, we invite you to follow us on LinkedIn or visit our website.