Problem:

The Challenge was to design and develop a product that would communicate with devices delivered by various vendors in the same building. Typically, the Building Management systems use multiple products provided by multiple vendors in a single building. All devices provided by different vendors don’t work on a single protocol that makes it challenging to interact with the system.

Solution/Approach:

To resolve this challenge AmbiAutomation decided to customise the existing HVAC bridge board as per the connectivity requirements from the customer.

AmbiAutomation HVAC bridge board comes with various connectivity solutions like 4G, Wi-Fi, Ethernet, etc., for connecting with the outside world.

The HVAC bridge board was re-designed to gather data over an RS232, RS485 as well as IP (ethernet) from various systems and then forward the data to the server over a 4G connectivity.

The HVAC bridge board has been successfully configured to communicate with systems and sensors from the followings:

- Daikin

- Delta

- ABB

- IFM(sensors)

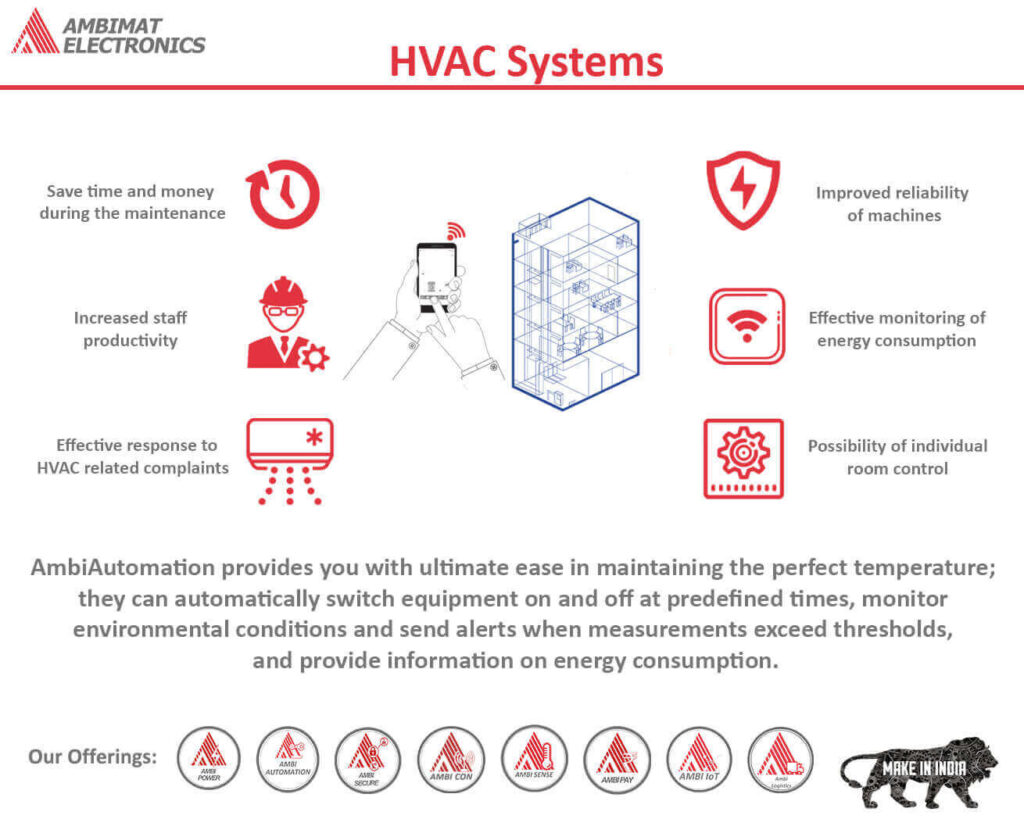

It helped in protecting most costly equipment by allowing to keep close tabs on every activity of the equipment and ensure it functions properly.

It simplifies the management of the facility, making it easy to access and control any area of your building’s operations.

All of these features helps your building to operate more cost-efficiently through automatic scheduling and occupancy controls.